The Protection Misconception Surrounding Safety Helmets

Jul 06, 2021 • NEWS & EVENTSMino Alkhawam, Product Manager – Head Protection

According to a report from the American Journal of Industrial Medicine, construction workers have the highest rate of brain injuries among U.S. workers – both fatal and nonfatal. Traumatic brain injuries represented 25% of all construction fatalities and 24% of all occupational traumatic brain injury fatalities. The report cited the leading causes of traumatic brain injuries for construction workers to be falls from roofs, ladders and scaffolds.1

THE RISING USE OF SAFETY HELMETS AMONG CONSTRUCTION COMPANIES

With studies reporting such staggering statistics as these, it’s no surprise that head protection has become a popular topic in discussions surrounding construction worker safety. It also may explain why more and more construction companies have been exploring the use of safety helmets, rather than traditional hard hats, when assessing their head protection needs. This trend can be attributed to the perception that all safety helmets provide the same enhanced level of head protection by protecting workers from both top-of-head and side impact hazards. This misconception assumes that safety helmets possessing a foam liner, a common feature among safety helmets, will protect to the equivalent of a Type II style, which is not true. The foam liner is not what escalates a safety helmet from providing Type I to Type II protection. Specific testing is required in order to receive Type II status, which is what renders the helmet effective in protecting against side impact. The first step in unveiling any protection misconceptions is understanding the difference between Type I and Type II hard hats or safety helmets.

THE DIFFERENCE BETWEEN TYPE I AND TYPE II PROTECTION

TYPE I (Top Impact)

Designed to reduce the force of impact to the top of the head

TYPE II (Top and Lateral Impact)

Offers side (lateral) impact protection which reduces the force of impact resulting from a blow which may be received off center as well as to the top of the head

The main difference between Type I and Type II hard hats and safety helmets is the type of impact that they protect against:

- > Type I styles are designed to reduce the force of impact located at the top of the head only

- > Type II styles are designed to reduce the force of impact at both the top and the sides of the head

This element is straightforward. However, an additional component that distinguishes Type I styles from Type II styles is that Type II styles are subjected to more testing. Both Type I and Type II hard hats are subject to penetration testing, but:

- > Type I styles are only tested at a single position, compared to Type II styles, which are also subjected to an off-center penetration test

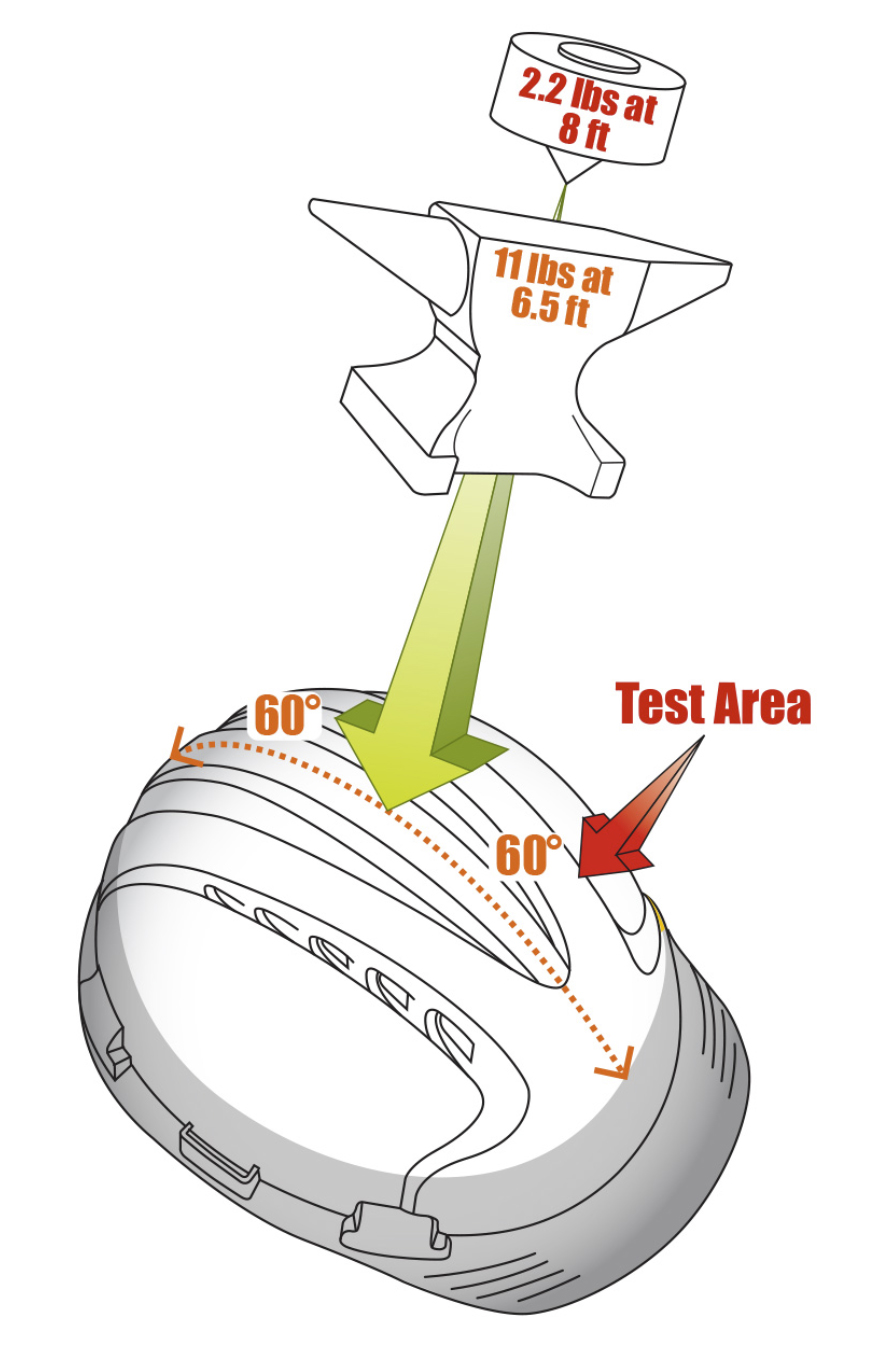

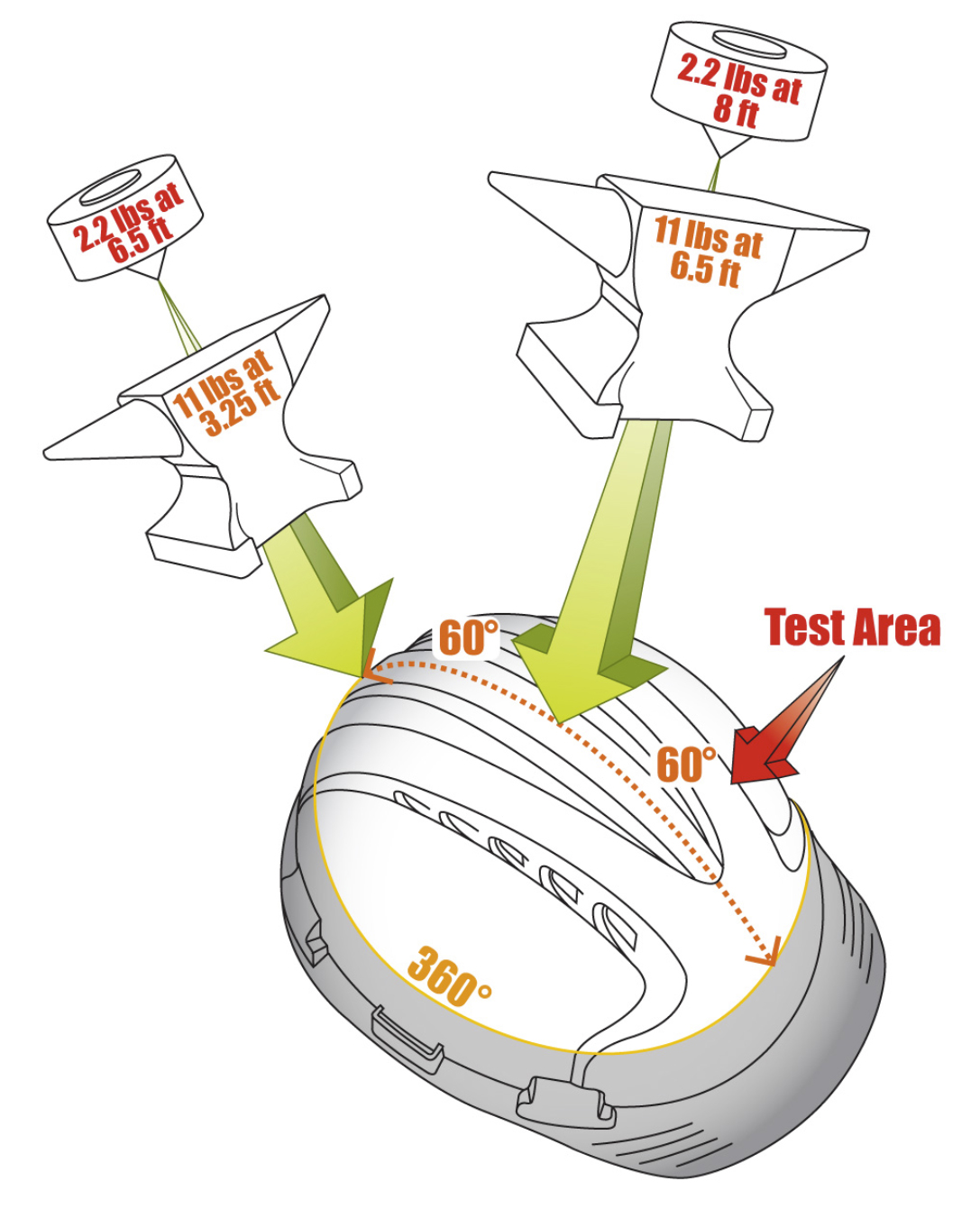

- > Type II styles must also go through an Impact Energy Attenuation test

The Impact Energy Attenuation test is different than the force impact test because this test has the protector falling to strike an object, instead of force impact tests, which have an object striking the protector. This is intended to represent a real-world situation where a worker may strike an object during a slip or fall. This scenario aligns with what the report we referenced at the beginning of this article attributed most traumatic brain injuries to – construction workers falling or slipping from roofs, ladders and scaffolds.

There’s one final difference in the testing that Type II styles are subject to in comparison to Type I styles – this one relates to the chin strap. If a Type II hat is provided with a chin strap, there’s an additional testing procedure for the retention and elongation of the chin strap. On Type I hats, there is no chin strap retention test that’s required to meet the ANSI Z89.1 standard.

THE ROLE WORK ENVIRONMENT PLAYS

When identifying which type of head protection fits your needs – a Type I or Type II style – evaluating your work environment and assessing the hazards is critical. Your work environment plays a crucial role because you may not require the additional protection that comes with a Type II style. Here are a few questions you can ask to determine the right level of protection for your application:

- > Will the workers consistently be working at heights?

- > Do the conditions or situations present a concern for enduring impact on the sides of the head?

- > Is there a risk of a worker’s head striking an object, instead of just an object striking the hat only at the top of the shell?

Due to the varying hazards when working at heights, a safety helmet may be the best fit for you if it is tested to ANSI Z89.1 Type II standards. That is the only way to guarantee you are receiving an increased level of protection from falls or slips. While there are other standards that are enforced or adopted in markets across the world, it is important to remember that in the United States, OSHA has only adopted the ANSI Z89.1 standard for head protection. Compliance enforcement and judgment of whether the level of protection is adequate is only based on compliance with ANSI Z89.1, not any other standard in any other market worldwide.

In summary, it is important to recognize the differences between the testing requirements of Type I and Type II styles. Additional features, such as a foam liner or chin strap, does not make a Type I hard hat offer equivalent protection to a Type II. Assessment of the potential workplace hazards is also crucial to determining which product will provide the best protection for the work environment.

DISCOVER THE BEST TYPE OF HEAD PROTECTION FOR YOUR APPLICATION

Since there are so many different industries and applications where head protection is required, there are multiple categories and styles of head protection to consider. Evaluating the work environment and assessing the hazards is a critical first step.

PIP® offers an extensive line of Type I and Type II hard hats and safety helmets that protect workers from falling objects in multiple industries, from heavy-duty mining to residential construction. Our Dynamic® line of head protection is also produced in North America using state-of-the-art robotic manufacturing.

Discover the right head protection for your needs here

REFERENCES:

1. Tiesman H, Konda S, Reichard A (2016). Fatal traumatic brain injuries in the construction industry: 2003−2010. Am. J. Ind. Med. 59:212–220.

This article was originally published in OH&S Magazine’s January/February 2020 issue and has been modified to reflect current market trends.

MORE ARTICLES

Empowering Electrical & Utility Workers: PIP Global Safety Exhibits at IEE PES T&D 2024

PIP Global Safety team members recently returned from a successful IEEE PES T&D show, an event that gathers power and energy professionals from across the globe joining forces to tackle the industry's m…

READ MOREPIP® G-Tek®PolyKor™ D3O®iP™ Wins the 2024 OH&S Industrial Hygiene Award

PIP® has been selected as the 2024 Occupational Health & Safety Industrial Hygiene Award Winner in the hand protection category for the G-Tek®PolyKor™ D3O®iP™ l…

READ MORETrends in personal protective equipment 2020

Joseph Milot III, director of product management, Protective Industrial Products Inc. (PIP), discusses eyewear and protective clothing trends for 2020. For protective clothing, there’s been an i…

READ MOREReusable vs. Disposable PPE: Why Switching to Gear You Can Reuse Makes Good Financial Sense

Nora Kirby, national account manager for Protective Industrial Products (PIP), weighs in on why switching to reusable PPE is a favorable alternative to using disposables amid the global pandemic. With disposable PPE in…

READ MOREWhy this New York glove supplier bought an ear plug maker from California

Protective Industrial Products in Latham, New York, added 100 employees and expanded its presence in the food, drug and retail sectors when it acquired ear plug maker Hearos LLC of California last week. "We are a lea…

READ MORETrends in Hearing Protection

Approximately 22 million workers are exposed to potentially damaging noise on the job every year, according to OSHA. Damaging noise can result in noise-induced hearing loss – something that OSHA no…

READ MOREPIP Acquires Georgia Glove Maker

Protective Industrial Products in Latham, New York has acquired Century Glove Inc. in Summerville, Georgia. It is the 20th acquisition for Joe Milot since 1984 when he had a disagreement with his bosse…

READ MORE10 minutes with Bridget Milot of PIP

Bridget Milot remembers waking up in the middle of the night to the sound of invoices rolling across the fax machine when she was a little girl. She was 12 years old the first time her father, Joe Milot…

READ MOREBig data will help this company sell more gloves, goggles and hard hats

Bridget Milot believes that big data and a bigger information technology department will position Protective Industrial Products to gain a larger share of the market for safety goggles, hard hats and gl…

READ MORETrends in Hearing Protection

Hearing loss is preventable. Why, then, is it still so common? NIOSH notes that occupational hearing loss is one of the most common work-related illnesses in the United States. And according to OSHA, ap…

READ MORETrends in Eye Protection

In 2014, nearly 24,000 eye injuries involving days away from work occurred, the Bureau of Labor Statistics states. Workplace-related eye injuries can have lasting and devastating consequences. However, th…

READ MOREGlove and hard hat supplier doubles sales as construction and manufacturing grow

A rebound in the automotive and construction industries have helped Joe Milot's company double its revenue over the last five years.Milot is founder and president of Protective Industrial Products Inc., a …

READ MOREThe State Of The Personal Protective Equipment Market

During the STAFDA 2015 Convention on Nov. 9 in Phoenix, AZ, the event's general session that morning included a "state of the industry" report on personal protective products from Robin Roberts, Vice Pr…

READ MORETrends in Protective Clothing

For workers who wear protective clothing, getting dressed for the workday is serious business. Take a construction worker performing night work, for example. High-visibility clothing can help him be se…

READ MORESTAFDA Announces Convention Keynote Speakers, Theme

The Specialty Tools and Fasteners Distributors Association recently announced the keynote speakers and theme for this year's 39th Annual STAFDA Convention and Trade Show, held Nov. 8-10 in Phoenix.STAFDA…

READ MORELatham Glove Manufacturer Names New CFO

Protective Industrial Products has named Sean Weil as the Latham, New York-based manufacturer's new chief financial officer.Protective Industrial supplies hard hats, work gloves, safety goggles and refl…

READ MORENew tenant taking Plug Power's space at headquarters

A manufacturer in New York's Capital Region will take over the street-front offices at the headquarters of Plug Power Inc., the Latham, NY fuel-cell maker.By year's end, Protective Industrial Products…

READ MOREPIP Wins Affiliated Distributors 2012 Supplier of the Year for Performance

PIP was recently honored for outstanding achievement in winning the Affiliated Distributors 2012 Supplier of the Year - Performance Award. To be recognized as a top performer in this esteemed group of…

READ MORE